Specialized Solutions for Manufacturing Excellence

From outdated processes to industry-leading efficiency. We deliver measurable improvements that hit your bottom line—hard.

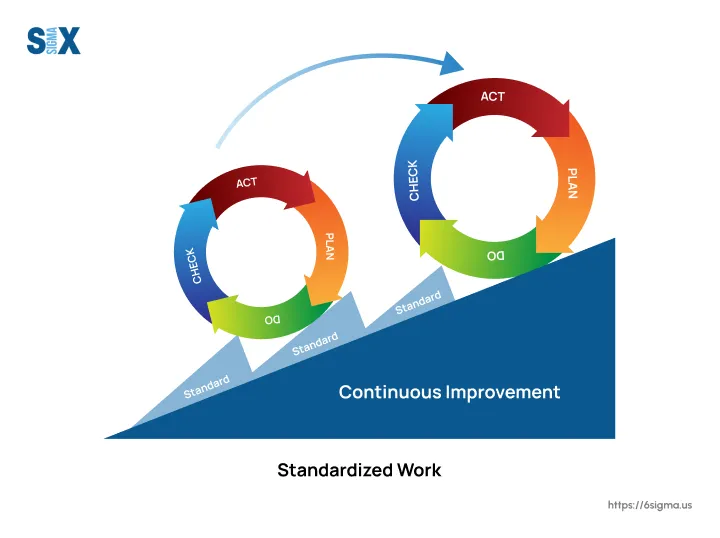

Lean Manufacturing Excellence

Transform your shop floor with proven Lean methodologies. We work side-by-side with your team to eliminate waste in all forms—overproduction, waiting time, excess inventory, unnecessary motion, defects, and overprocessing. Through Value Stream Mapping, 5S workplace organization, Standard Work, and Kaizen events, we help you build a sustainable culture where every employee is engaged in continuous improvement. This isn't just about tools—it's about changing how your organization thinks and operates.

Key Benefits:

- 15-30% productivity improvement within 6 months

- 40-60% reduction in defects and rework

- 30-70% reduction in lead times

- 20-50% reduction in inventory carrying costs

- Improved employee engagement and problem-solving skills

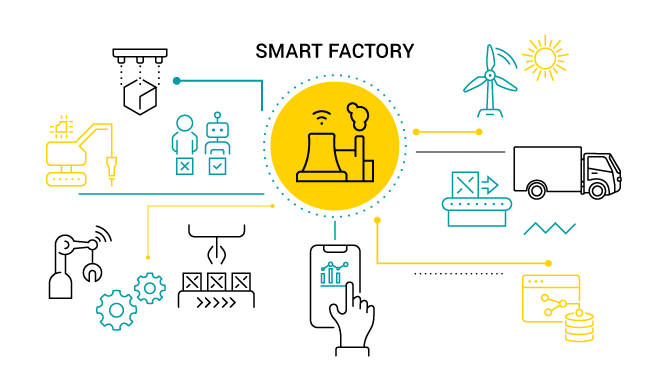

Smart Factory & Industry 4.0

Step into the future with Industry 4.0 technologies tailored for mid-sized manufacturers. We implement sensor networks, machine connectivity (IoT), real-time dashboards, predictive maintenance systems, and data analytics that actually drive decisions—not just look good on screens. Whether you're starting with basic machine monitoring or building a fully integrated smart factory, we guide you through the complexity with practical, ROI-focused solutions. Our approach bridges the gap between legacy equipment and cutting-edge technology.

Key Benefits:

- Real-time visibility into all production metrics

- 15-30% reduction in unplanned downtime through predictive maintenance

- Data-driven decision making at every level

- Remote monitoring and control capabilities

- Seamless integration with existing ERP and MES systems

Operational Excellence Program

Go beyond Lean with a holistic approach that touches every aspect of your operations. Our Operational Excellence Program integrates multiple improvement pillars—Lean Manufacturing, Total Productive Maintenance (TPM), Six Sigma Quality, Safety Excellence, and Supply Chain Optimization—into one cohesive strategy. Perfect for companies ready to compete globally or those preparing for major certifications. We deploy a structured roadmap with clear milestones, cross-functional teams, and leadership development to ensure lasting transformation.

Key Benefits:

- Multi-pillar approach addressing all operational dimensions

- 40-50% improvement in OEE (Overall Equipment Effectiveness)

- World-class quality standards and certifications

- Enhanced safety culture with measurable LTIR reduction

- Leadership capability building at all levels

Manufacturing Health Check & Strategy

Not sure where to start? Our Manufacturing Health Check is a comprehensive 8-10 week diagnostic that evaluates every aspect of your operations—from shop floor efficiency and quality systems to supply chain performance and organizational capability. We benchmark you against industry best practices, identify quick wins and long-term opportunities, and deliver a prioritized roadmap with clear ROI projections. Think of it as an MRI for your manufacturing operation—revealing exactly what's working, what's broken, and what to fix first.

Key Benefits:

- Comprehensive assessment across 50+ operational metrics

- Clear identification of improvement opportunities with ROI estimates

- Prioritized 12-24 month transformation roadmap

- Benchmark analysis against industry leaders

- Executive summary with actionable quick wins (30-90 days)

Greenfield Manufacturing Projects

Building a new factory or production line? Don't replicate old problems in a new building. Our Greenfield Project expertise ensures you design excellence from the ground up—optimal facility layout, right-sized equipment, efficient material flow, built-in quality systems, and digital infrastructure ready for Industry 4.0. We guide you through site selection, capacity planning, equipment procurement, process design, and startup—delivering a facility that's lean, agile, and profitable from day one. Perfect for expansions, new product lines, or entirely new manufacturing sites.

Key Benefits:

- Optimized factory layout and material flow design

- Right-first-time equipment selection and procurement support

- 25-40% lower operational costs vs. typical greenfield startups

- Faster ramp-up to full production capacity

- Built-in Lean and digital systems from day one

Our Service Delivery Process

A proven methodology that ensures successful implementation and sustainable results.

1. Assess

Comprehensive assessment of current operations, identifying improvement opportunities and establishing baseline metrics.

2. Design

Design practical solutions tailored to your specific challenges, focusing on simplicity, sustainability, and results.

3. Implement

Hands-on implementation alongside your team to ensure real results and build internal capabilities.

4. Sustain

Establish systems to maintain improvements through visual management, standard work, and regular reviews.

Ready to Transform Your Manufacturing?

Schedule a consultation to discuss your specific challenges and discover how our services can drive your success.